PANEL SAW

Salient Features

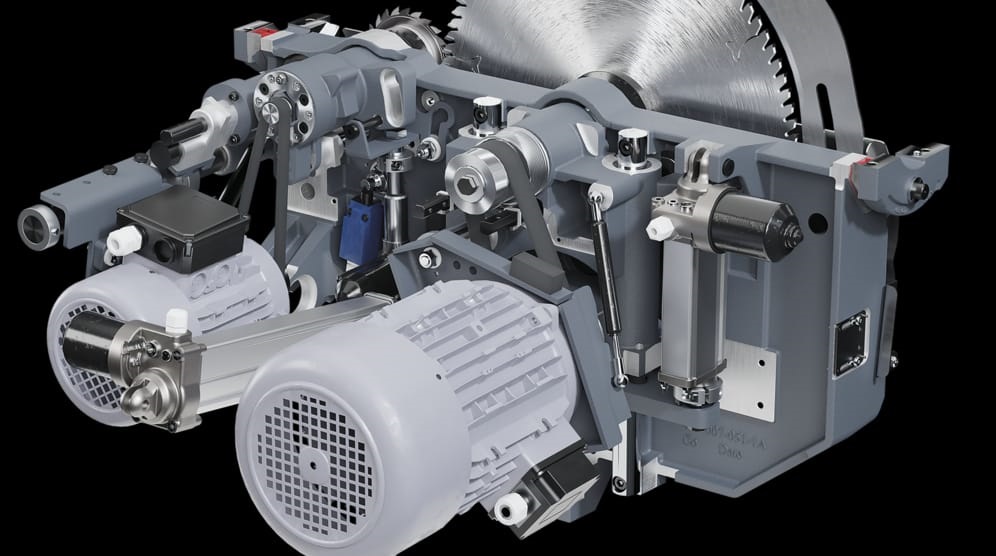

- Able to mount maximum 300 mm (12") saw blade

- Two speed for saw blade

- Independent motor for main blade and scoring unit

- Analog readout of saw unit tilt

- 90° quick positioning design on cross cut fence

- Heavy duty bracket to give reliable accuracy

- Enlarged sliding carriage for stronger support cutting

Our masterpiece for your success

An overview of key features.

45 angel digital display

A panel saw machine with a 45-degree angle digital display ensures precise angled cuts for projects requiring bevel or miter edges. The digital display allows for easy adjustments and real-time accuracy, reducing errors and improving efficiency.

Heavy saw unit

The heavy saw unit in a panel saw machine provides robust cutting power, ideal for handling thick or dense materials with ease. Designed for durability and stability, it ensures smooth, accurate cuts even in demanding industrial environments.

Slider Push Button

The slider push button on a panel saw machine allows for quick and easy control of the sliding table, ensuring smooth material movement during cutting. This feature enhances operator convenience and accuracy, enabling efficient handling of large panels with minimal effort.

Multy Layer Board

The multi-layer board feature in a panel saw machine allows for precise cutting of layered materials, such as plywood or composite boards, without compromising on accuracy. This capability ensures clean, even cuts across all layers.

Alluminium Alloy

The aluminum alloy construction in a panel saw machine offers a lightweight yet durable framework, ensuring long-lasting performance and stability. This material is resistant to corrosion and wear, making it ideal for high-precision cutting tasks while maintaining the machine's structural integrity.

Solid Wood Board

The solid wood board feature in a panel saw machine ensures precise and clean cuts on natural wood materials, maintaining the quality and integrity of the wood grain. Designed to handle dense and thick wood boards

Density Board

Panel saw machines are ideal for cutting density boards precisely and efficiently. These machines feature a robust construction, powerful motors, and adjustable cutting depths to handle various board thicknesses.

Manual Panel Saw

Manual panel saws are a reliable and cost-effective solution for cutting panels of various materials, including wood, plastics, and composites. These saws feature a sturdy construction, manual controls for precise adjustments, and a powerful cutting blade.

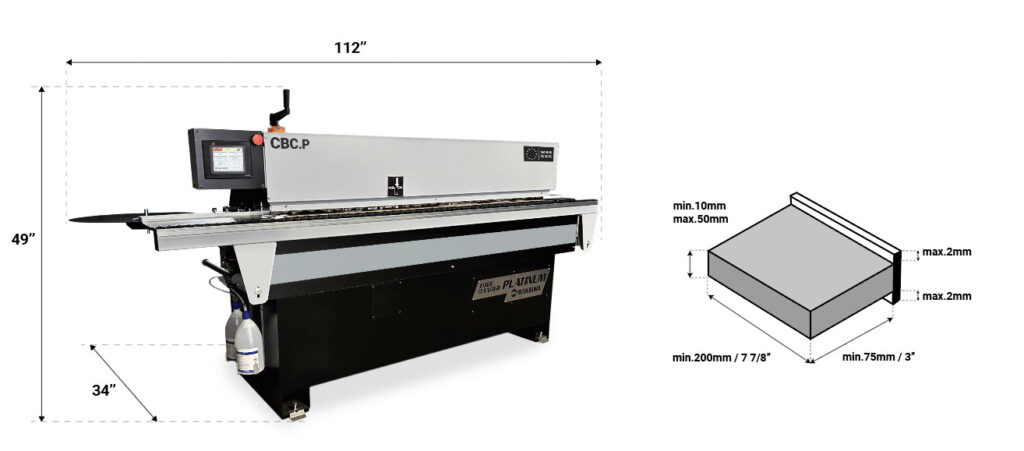

Dimension of Panel Saw

Panel Saw Specification

| Specifications | N375E | N375S | N375U |

|---|---|---|---|

| SLIDING TABLE | 3200 X 375 MM EUROPEAN | 3200 X 375 MM EUROPEAN | 3200 X 375 MM EUROPEAN |

| MAIN MOTOR | 1.5HP | 5HP/7.5HP | 5HP/7.5HP |

| SCORER MOTOR | 5HP | 1.5HP/2HP | 2.5HP/2HP |

| MAX DEPTH OF CUT | 115MM | 115MM | 115MM |

| MAIN SAW DIA | 400 MM MAX | 400 MM MAX | 400 MM MAX |

| SCORER DIA | 120MM | 120MM | 120MM |

| MAIN SAW INNER DIA | 30 MM | 30 MM | 30 MM |

| SCORER INNER DIA | 20 MM | 20 MM | 20 MM |

| SCORING LATERAL MOVEMENT | MAN +- 3MM | MAN +- 3MM | MAN +- 3MM |

| SCORING UP-DOWN | AUTO | AUTO | AUTO |

| MAIN SAW UP-DOWN | MOTORISED | MOTORISED | MOTORISED |

| BACK REFENCE MAX CUT | 1280 MM | 1280 MM | 1280 MM |

| FRONT REFENCE MAX CUT | 1800 MM (3300 MM EXTNDED) | 1800 MM (3300 MM EXTNDED) | 1800 MM (3300 MM EXTNDED) |

| TILTING MOVEMENT | TILTING MOVEMENT 0O TO 45O MANUAL ( DIGITAL ) | 0O TO 45O MANUAL ( DIGITAL ) | 0O TO 45O MOTORISED ( DIGITAL ) |

| BACK REFENCE LOCKING | MANUAL | PNEUMATIC | PNEUMATIC |

| BACK REFENCE | SCALE | DIGITAL | DIGITAL |

| BACK SUPPORT ROLLER | EXTRA | INCLUDED | INCLUDED |

| FRONT REFENCE DIGITAL READOUT | EXTRA | EXTRA | INCLUDED |

| ON/OFF SWITCH ON SLIDING TABLE | OPTIONAL | INCLUDED | INCLUDED |

| OVERALL DIMENSIONS | 3300 X 3200 X 950 MM | 3300 X 3200 X 950 MM | 3300 X 3200 X 950 MM |

| PACKING DIMENSIONS | 1050 X 3200 X 1050 MM | 1050 X 3200 X 1050 MM | 1050 X 3200 X 1050 MM |

| APPROX WEIGHT | 750 TO 850 KG | ||

The panel saw offers a maximum cutting length of 3200 mm and width

of 1250 mm, with a cutting thickness of up to 85 mm. It is equipped with

a high-precision main saw blade (300 mm – 400 mm) operating at 4000 – 6000 RPM and a scoring saw blade (120 mm) running at 8000.

Driven by a robust main motor and a scoring saw motor, the machine ensures

smooth and powerful operation. It also includes a 100 mm dust port for efficient extraction, achieving a 80% dust collection rate.

The machine includes an anodized aluminum sliding table, tilt adjustment from 0° to 45° And Automatic Scoring Up-Down.

Optional features like an Digital Readout, Sliding Start-Stop, And Support Roller.

A PANEL SAW MACHINE is an essential piece of equipment in woodworking and furniture manufacturing, designed to accurately cut large panels of wood, plywood, MDF, and other sheet materials into smaller, precise sizes.

Typically used in workshops and industrial settings, the panel saw is known for its efficiency, versatility, and precision. It features a robust frame, a sliding table, and a powerful motor that drives the cutting blade, allowing for smooth and straight cuts.

The machine is equipped with a main saw blade and a scoring blade, which work together to ensure clean and chip-free edges, particularly on laminated materials.

Advanced models often include digital controls and adjustable cutting angles, enhancing accuracy and ease of operation.

Download Catalog

A panel saw machine is an essential tool designed to efficiently cut large sheets of materials like wood, plastic, and metal with precision. Ideal for industries such as woodworking, furniture manufacturing, and construction, panel saws provide clean, accurate cuts on large panels.

Related Products

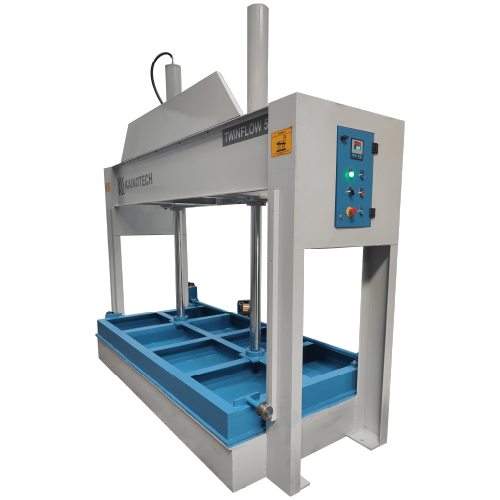

COLD PRESS

A COLD PRESS MACHINE is essential in woodworking and furniture manufacturing, used primarily for bonding veneers, laminates, and other materials to substrates like wood or MDF.

MANUAL EDGEBANDER

A MANUAL EDGEBANDER is a practical and cost-effective machine used in woodworking for applying edge banding materials to the edges of panels, such as plywood, MDF, or particleboard

CNC ROUTER

A CNC ROUTER is a versatile and precise machine widely used in woodworking, metalworking, and signage industries.

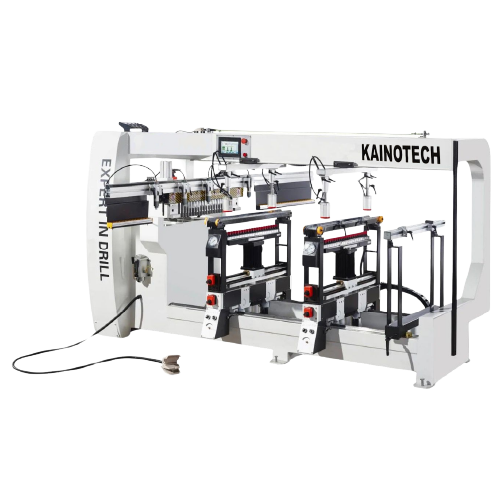

MULTI BORING

A MULTI-BORING MACHINE is an essential tool in the woodworking and furniture manufacturing industries, designed for drilling multiple holes simultaneously with high precision.

DUST COLLECTOR

A dust collector machine is an essential industrial device designed to improve air quality by capturing and filtering dust, debris, and other pollutants generated during manufacturing processes.