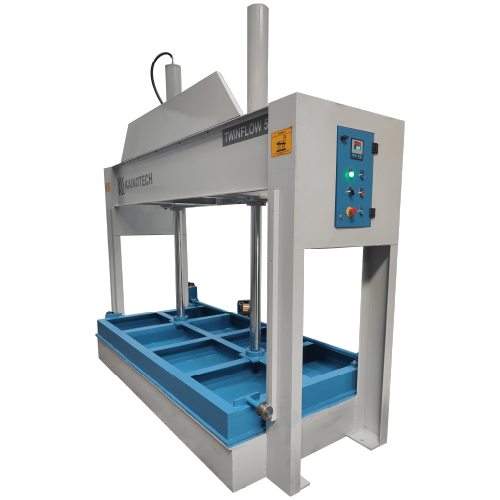

MEMBRANE VACUUM PRESS

Achieve Flawless Finishes with Our Advanced Membrane Vacuum Press

Salient Features

- Able to mount maximum 300 mm (12") saw blade

- Two speed for saw blade

- Independent motor for main blade and scoring unit

- Analog readout of saw unit tilt

- 90° quick positioning design on cross cut fence

- Heavy duty bracket to give reliable accuracy

- Enlarged sliding carriage for stronger support cutting

Our masterpiece for your success

An overview of key features.

Digital Timer

The digital timer on a membrane vacuum press machine allows for precise control over the pressing time, ensuring optimal adhesion and finish quality.

Digital Temprature Meter

The heavy saw unit in a panel saw machine provides robust cutting power, ideal for handling thick or dense materials with ease. Designed for durability and stability, it ensures smooth, accurate cuts even in demanding industrial environments.

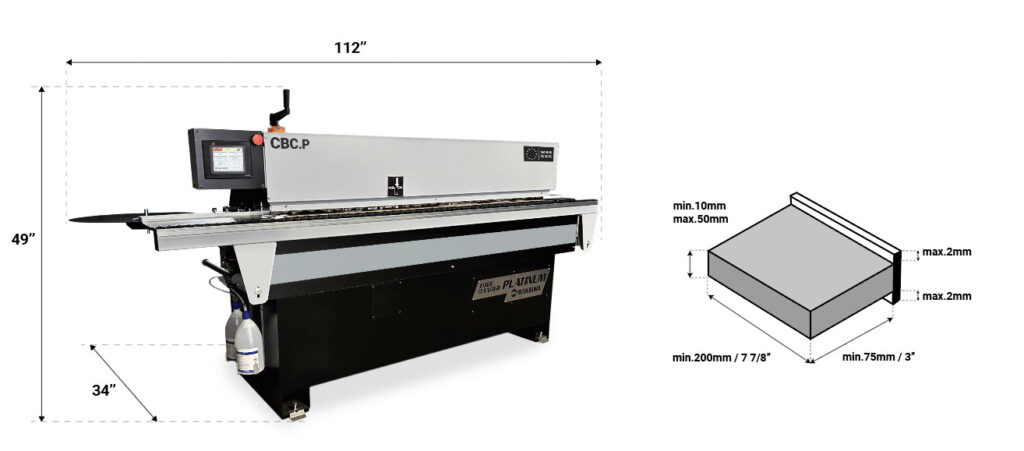

Dimension of Membrane Vacuum Press

Membrane Vacuum Press Specification

| Specifications | HEATSYNC – B | HEATSYNC – H | |

|---|---|---|---|

| Thickness of work piece | 12-70MM | 12-70mm | |

| Worktable size | 2550 X 1300 MM | 2550 X 1300 MM | |

| Vacuum pressure | -0.1 Mpa | -0.1 Mpa | |

| Total power | 28 HP | 28 HP | |

| Vacuum pump | 3 HP | 3 HP | |

| SCORER DIA | 120MM | 120MM | 120MM |

| Working trolley | 1 + 1 (Optional) | 1 + 1 (Optional) | |

| Heating element | Bulb | Heater | |

| Overall dimensions | 6870 X 1850 X 1450 MM | 6870 X 1850 X 1450 MM | |

| Working mode | MAN/AUTO | MAN/AUTO | |

| Overall dimensions with optional trolley | 10470 X 1850 X 1450 MM | 10470 X 1850 X 1450 MM | |

| Approx weight | 1100 KG | 1150 KG |

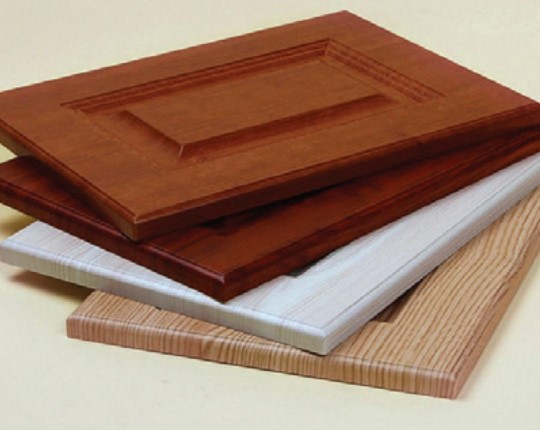

A membrane vacuum press is an advanced industrial machine used for laminating,

forming, and veneering materials such as wood, MDF, or composites. It operates by applying uniform pressure using a flexible membrane and a vacuum system, ensuring

that the material conforms tightly to the shape of the mold or surface being laminated.

This process results in high-quality finishes, perfect for creating smooth, durable surfaces in cabinetry, furniture manufacturing, and other applications requiring precision

and aesthetic appeal. The machine enhances productivity and guarantees consistency in both small and large-scale production.

Download Catalog

A membrane vacuum press machine is designed to provide flawless finishes for woodworking, laminating, and veneering applications. It uses vacuum pressure and a flexible membrane to mold and press materials onto surfaces, ensuring a smooth, high-quality bond. Ideal for creating intricate designs on wood, MDF, and other materials, the machine is perfect for cabinetry, furniture manufacturing, and interior design projects.

Related Products

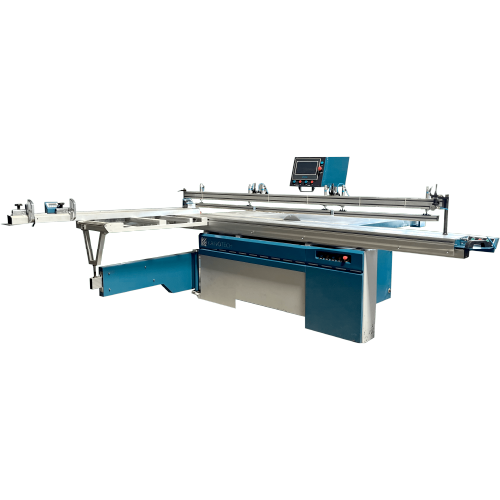

A PANEL SAW MACHINE is an essential piece of equipment in woodworking and

furniture manufacturing, designed to accurately cut large panels of wood, plywood,

MDF, and other sheet materials into smaller, precise sizes.

Panel Saw

An AUTO PANEL SAW MACHINE is a highly efficient and precise tool used in woodworking

and furniture manufacturing.

Auto Panel Saw

A COLD PRESS MACHINE is essential in woodworking and furniture manufacturing,

used primarily for bonding veneers, laminates, and other materials to substrates like

wood or MDF.

Cold Press

A MANUAL EDGEBANDER is a practical and cost-effective machine used in woodworking

for applying edge banding materials to the edges of panels, such as plywood,

MDF, or particleboard

Manual Edge Bander

An Automatic edge bender is a high-efficiency machine used in woodworking and furniture manufacturing to apply edge banding to the exposed edges of materials like

plywood, MDF, or particleboard.

Automatic Edgebander

A CNC ROUTER is a versatile and precise machine widely used in woodworking, metalworking,

and signage industries.

CNC Router

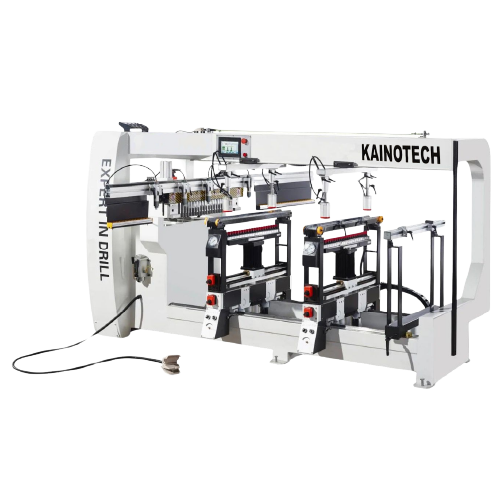

A MULTI-BORING MACHINE is an essential tool in the woodworking and furniture

manufacturing industries, designed for drilling multiple holes simultaneously with high

precision.

Multi Boring

A dust collector machine is an essential industrial device designed to improve air

quality by capturing and filtering dust, debris, and other pollutants generated during

manufacturing processes.

Dust Collector

Previous

Next