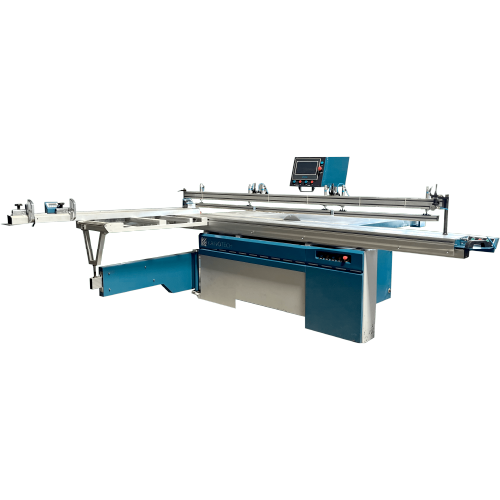

AUTO PANEL SAW

Salient Features

- Heavy Duty Precision sliding table with bearing developed with advanced technology with multi chamber system for maximum rigidity of the double roller carriage

- Sturdily built heavy duty m/c. for precise burr free cutting

- Made in India with best service support & very economical spares

Our masterpiece for your success

An overview of key features.

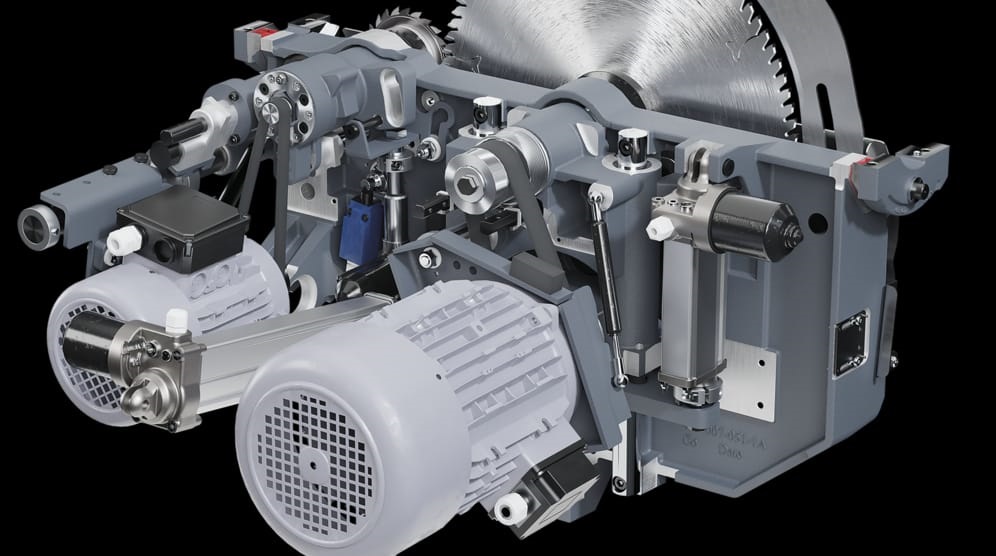

Heavy Saw Unit

The heavy saw unit in a auto panel saw machine provides robust cutting power, ideal for handling thick or dense materials with ease. Designed for durability and stability, it ensures smooth, accurate cuts even in demanding industrial environments.

435 MM European slider

Auto panel saw machines equipped with a 435mm European slider offer exceptional precision and cutting capacity. The European slider system ensures smooth and accurate movement of the cutting table, allowing for precise cuts in various panel materials.

HMI One Touch Control System

An HMI One Touch Control System offers a user-friendly and efficient interface for operating machinery. This system typically features a touch screen display that allows operators to control various functions with a simple tap.

Multy Layer Board

The multi-layer board feature in a auto panel saw machine allows for precise cutting of layered materials, such as plywood or composite boards, without compromising on accuracy. This capability ensures clean, even cuts across all layers.

Alluminium Alloy

The aluminum alloy construction in a auto panel saw machine offers a lightweight yet durable framework, ensuring long-lasting performance and stability. This material is resistant to corrosion and wear, making it ideal for high-precision cutting tasks while maintaining the machine's structural integrity.

Solid Wood Board

The aluminum alloy construction in a auto panel saw machine offers a lightweight yet durable framework, ensuring long-lasting performance and stability. This material is resistant to corrosion and wear, making it ideal for high-precision cutting tasks while maintaining the machine's structural integrity.

Density Board

Auto Panel saw machines are ideal for cutting density boards precisely and efficiently. These machines feature a robust construction, powerful motors, and adjustable cutting depths to handle various board thicknesses.

Slider Push Button

A slider push button is a type of electrical switch designed to provide a smooth and tactile feel when activated. It features a sliding mechanism that moves back and forth, completing an electrical circuit when in a specific position.

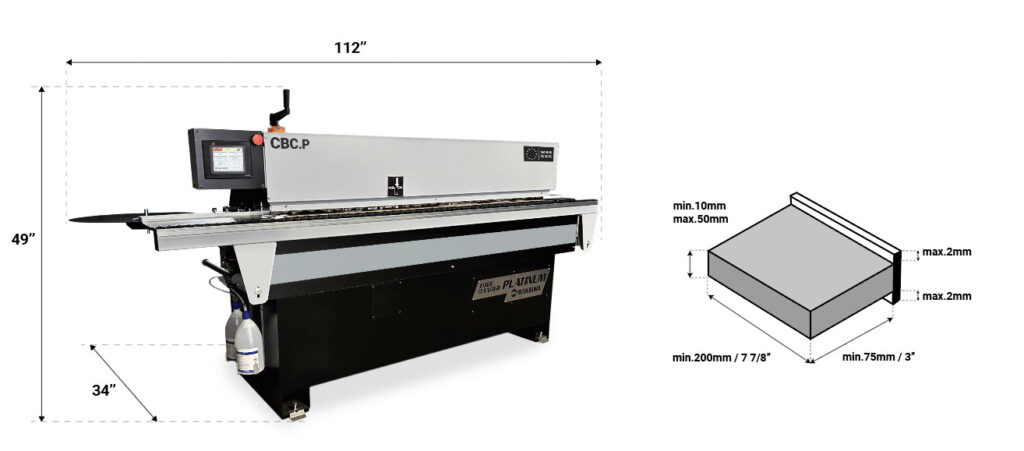

Dimension of Panel Saw

Auto Panel Saw Specification

| Specifications | N435X |

|---|---|

| SLIDING TABLE | 3200 X 435 MM EUROPEAN |

| MAIN MOTOR | 7.5HP/10HP |

| SCORER MOTOR | 2HP |

| MAX DEPTH OF CUT | 115MM |

| MAIN SAW DIA | 400 MM MAX |

| SCORER DIA | 120MM |

| MAIN SAW INNER DIA | 30 MM |

| SCORER INNER DIA | 20 MM |

| SCORING LATERAL MOVEMENT | MAN +- 3MM |

| SCORING UP-DOWN | AUTO |

| MAIN SAW UP-DOWN | MOTORISED |

| BACK REFENCE MAX CUT | 1280 MM |

| FRONT REFENCE MAX CUT | 1800 MM (3300 MM EXTNDED) |

| CROSS CUT FENCE | FRONT REFENCE WITH AUTO SCALE ADJUSTMENT |

| TILTING MOVEMENT | 0O TO 45O AUTOMATIC |

| BACK REFENCE | AUTOMATIC |

| BACK SUPPORT ROLLER | INCLUDED |

| FRONT REFENCE DIGITAL READOUT | INCLUDED |

| ON/OFF SWITCH ON SLIDING TABLE | INCLUDED |

| INTERFACE | TOUCH PANEL WITH PLC BASED CONTROLLING SYSTEM ( DELTA ) |

| OVERALL DIMENSIONS | 3300 X 3200 X 950 MM |

| PACKING DIMENSIONS | 1150 X 3200 X 1050 MM |

| APPROX WEIGHT | 1250 TO 1300 KG |

Download Catalog

Related Products